Blog

Efficient Production Logging: Techniques for Maximizing Well Performance

Efficient Production Logging: Techniques for Maximizing Well Performance

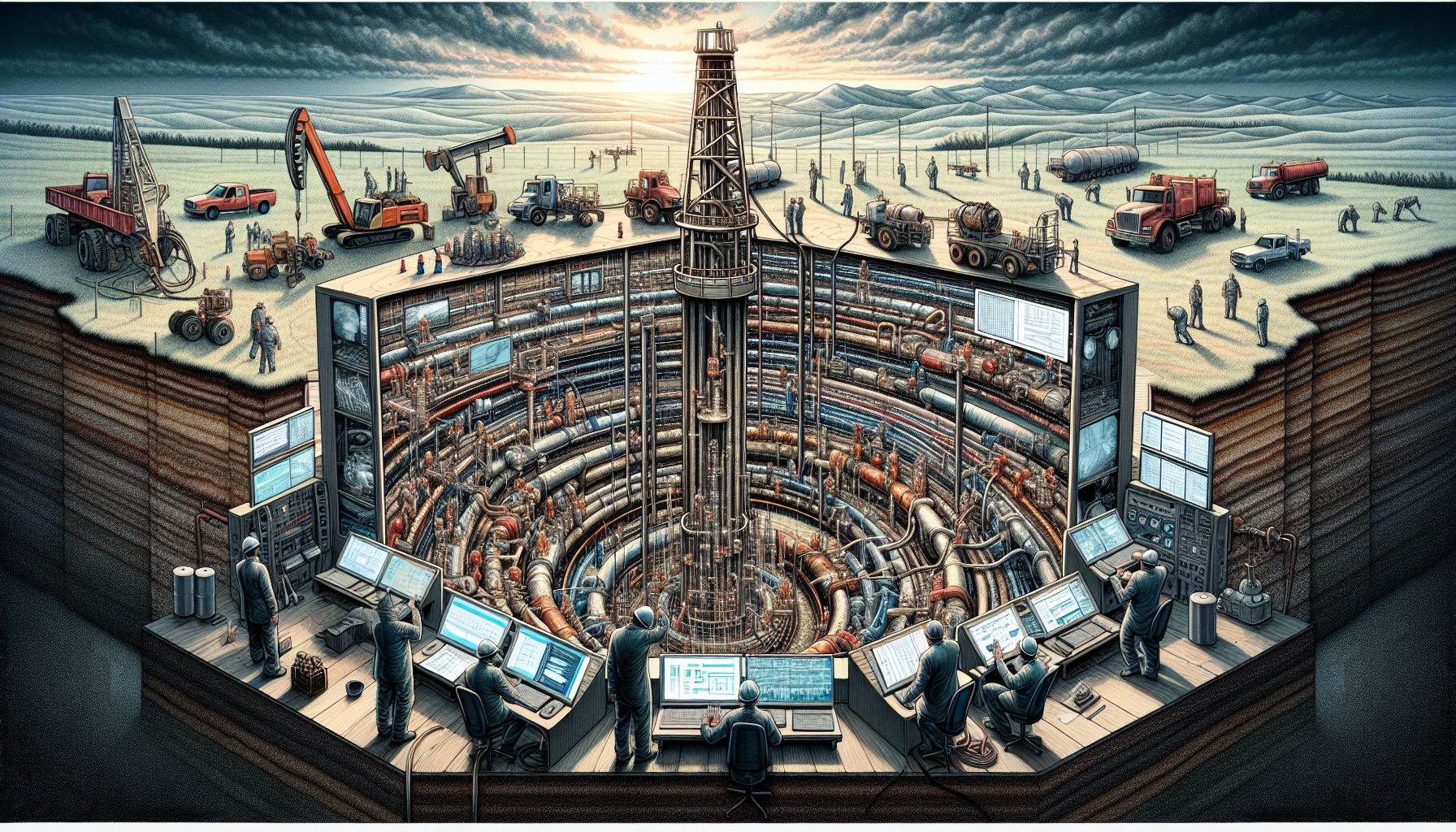

To boost well performance, an in-depth understanding of production logging within the wellbore is crucial. This article sheds light on the pivotal techniques and tools that enable precise fluid analysis and evaluation of well performance. Discover the role of multiphase flow analysis, the impact of technological advancements, and how this data guides strategic decision-making for improved reservoir management - all essential components of effective production logging.

Key Takeaways

Production logging requires the use of multiple tools, significant expertise, and a detailed pre-job meeting to outline objectives and ensure alignment with performance improvement goals.

Advanced technology and specialized software solutions like PLATO have significantly improved production logging, enabling comprehensive analysis with features such as emulating complex flow profiles, modeling multiphase well activity, and adjusting for various logging speeds.

Interpreting production logs is a complex process requiring expert-level knowledge; utilizing the data for reservoir management strategies and well completion can optimize production operations and extend the economic lifespan of oilfields.

Understanding Production Logging

To truly comprehend production logging, it’s essential to debunk a common myth: One tool is not enough. Contrary to popular belief, a comprehensive understanding of production logging necessitates the use of multiple tools. It defies the misconception that anomalies can be easily detected from a casual scan of the log.

The main applications of production logs are to:

Identify and quantify flow in and around pipes

Evaluate well or reservoir performance

Decipher the myriad types of fluid movements

Understand the unique applications each type has

However, the interpretation of these logs is not a task for the untrained eye. It requires a significant amount of education and experience due to the diverse types of logs and their distinct applications. The complexities of identifying different logging speeds, production regimes, and well logging techniques make expertise in this field all the more valuable.

Key Objectives of Production Logging

Behind the intricate process of production logging lie a few key objectives, central to its purpose and its value. The heart of production logging is the evaluation of fluid production and movement inside and outside the wellbore casing downhole. But how exactly is this achieved?

The answer is an array of logging tools. Some of the logging tools used to identify fluid types and flow characteristics in a well include:

Temperature logs

Radioactive-tracer logs

Spinner-flowmeter logs

Multiphase flow logging tools

These tools serve to measure fluid velocity and determine flow rates in a fluid flow stream, using spinner flowmeters calibrated through upward and downward passes at varying logging speeds. By considering fluid density, these measurements can be even more accurate.

Pre-Job Meeting Insights

Before the production logging services commence, a crucial step lies in the form of the Pre-Job meeting. This meeting serves to outline and discuss the specific objectives for running the production logging services. But what exactly does this entail, and how does it contribute to the overall operation?

These meetings are a time to:

pinpoint issues such as areas of production decline and instances of high water production

identify problems and evaluate well completion efficiency

ensure that service objectives align with performance improvement

These insights lay the groundwork for a smooth and efficient production logging operation.

Optimal Tool Selection

As you can imagine, the success of a production logging operation heavily depends on the tools used. A well-equipped team with a comprehensive suite of production logging tools is more likely to gain a better understanding of well conditions. But how does one select the right tools?

The answer lies in predictive software with emulation packages. These packages can provide a glimpse into potential tool measurements, aiding in optimal tool selection for specific production logging scenarios. But the task doesn’t end at tool selection. Establishing an effective operating procedure that ensures data quality and result accuracy is equally crucial. The use of high-quality, versatile tools such as wireline and slickline is paramount in achieving accurate data acquisition at various logging speeds.

The Role of Multiphase Flow Analysis

In the world of production logging, multiphase flow analysis is indispensable. It provides a lens to understand complex flow patterns and diagnose well performance issues throughout the lifecycle of hydrocarbon field exploitation. But what makes it so crucial?

Multiphase flow within a wellbore can exhibit various flow regimes and is complicated by deviated wellbores. In horizontal wells, the stratification of fluids due to gravity can affect the operation of measuring equipment, leading to potential data inaccuracies. This is where multiphase flow analysis comes into play, using a variety of production logging methods to evaluate single-phase flow as well as more complex tools for multiphase flow and well completion evaluation.

Advancements in Production Logging Technology

The field of production logging has witnessed significant advancements over time. From advanced velocity sensors to multi-array production logging tools, the evolution of technology has significantly improved the accuracy and reliability of production logging data.

These advancements have also spurred the development of specialized software solutions, designed to manage various file formats and handle data from any production logging tool at different logging speeds. Such software packages, like PLATO, have revolutionized the ability to analyze array data, distributed temperature sensor data, and temperature log, representing a significant leap in production logging technology.

Software Solutions Like PLATO

One of the notable advancements in production logging technology is the emergence of powerful software solutions like PLATO.

PLATO is designed to:

Manage various file formats

Handle data from any production logging tool

Allow for the analysis of array data and distributed temperature sensor data

Load over 14,000 traces simultaneously

This software provides a comprehensive and efficient solution for analyzing production logging data.

Beyond its data handling capabilities, PLATO is adept at:

Emulating complex flow profiles within wells

Modeling up to four phases of well activity, including production, injection, and shut-in phases using surface rates as constraints, and evaluating well completion

Enhancing interpretation with detailed PVT correlations

Determining regimes

Estimating skin on production zones

Identifying thief zones

All of these features are pivotal for precise quality control and analysis.

This powerful software has earned the trust of both large and small oil & gas operators due to its powerful quality control and coherent global three-phase flow model.

Expertise Behind the Logs

While advanced tools and software contribute significantly to the success of a production logging operation, none of it would be possible without the expertise behind the logs. Production logs should only be operated by individuals or teams with expert-level knowledge to ensure accuracy and reliability.

Field engineers must be trained in various production logging techniques using practical scenarios to enable them to perform precise log interpretations at different logging speeds. The team responsible for production log interpretations is often composed of:

Field engineers with extensive experience

Master’s level petroleum engineers

PhD-level experts in multiphase production physics and reservoir engineering

This combination of expertise ensures that the data collected is analyzed accurately and effectively, contributing to the overall success of the production logging operation.

Interpreting Production Logs

Interpreting production logs is a complex task that requires significant expertise in understanding fluid movements within the wellbore. It’s a nuanced process that goes beyond simple data analysis, requiring the ability to identify normal patterns and distinguish anomalies that indicate potential well issues.

Proper training is vital in interpreting production logs. Participating in production logging courses provides individuals with the foundational skills necessary for basic log interpretation, which they can build on to develop further experience. Implementation of a consistent interpretation methodology ensures a clearer distinction between important and trivial features in production logs, thus supporting better decision-making for potential well interventions.

This rigorous approach to interpretation is crucial in supporting evidence-based decisions and contributing to the overall success of production logging operations.

Production Logging in Action

But where does all this knowledge, expertise, and technology come into play? In the field, production logging services provide valuable data for reservoir management, well performance improvement, and problem diagnosis. These services measure crucial parameters for decisions that enhance long-term reservoir production across diverse flow regimes and well geometries.

Through the analysis of fluid movement within the wellbore and quantification of flow rates, production logging aids engineers in planning remediation and improving well and reservoir performance. Problems such as water or gas breakthrough, crossflow in thief zones, and mechanical faults can be identified using production logging tools, mitigating production downtime. This data is invaluable in managing reservoirs, particularly in mature fields, to identify and address zones with excessive water production.

Case Studies from Field Engineers

Field engineers with extensive experience recognize the critical role production logging plays in optimizing production operations. These engineers have seen firsthand how proper utilization of production logging techniques can lead to notable improvements in well performance.

Insights gained from production logging have provided valuable data that enhanced reservoir performance and well completion efficiency, informing more effective reservoir management strategies. These real-world experiences underline the importance of production logging in the oil and gas industry and validate the investment in this vital service.

Utilizing Data for Reservoir Performance Strategies

Once the data is acquired, it’s time to put it to use. Production log data can be used to calibrate reservoir simulation models, assisting engineers in matching zonal contributions and refining parameters for more accurate reservoir management.

This utilization of accurate production data can increase the economic lifespan of mature oilfields, as well as optimize gas production. More than 60% of global oil fields employ reservoir characterization for enhanced oil recovery, according to the American Association of Petroleum Geologists. In fact, producing oil from these mature fields has become more efficient through such optimization techniques.

Analyzing historical production data from wells allows for the identification of reservoir performance trends and fluid movements within the wellbore, essential in crafting optimized future production strategies.

Maximizing Efficiency in Production Logging

In any operation, efficiency is key, and production logging is no exception. Proper depth control in production logging is achieved using devices such as a casing collar locator or radioactive markers, as well as by matching with other reference logs.

Efficiency in production logging can be maximized by using specialized tools to reduce the weight needed to overcome well pressure within the wellbore, reducing grease injection, and integrating reservoir evaluation services in a single logging run. For wells with deviation challenges and potential gas entries, noise logs, cement evaluation logs, and downhole video logs provide essential data for assessing well completion and addressing issues encountered.

Continuous log quality is maintained through standardized libraries, selective logging, clear descriptions, severity log levels, enabling production logging, and regular monitoring.

Cost Considerations and Value of Production Logging

While the benefits of production logging are clear, it’s crucial to consider the costs. However, the value received from accurate well analysis presents a strong return on investment. Production efficiency can be significantly enhanced by investing in production logging, with an increase of as much as 30%.

Accurate reservoir characterization through production logging within the wellbore is a critical factor in realizing such efficiency gains. Investing in production logging is essential for detailed well analysis and making informed decisions on well performance management. While pricing structures for production logging vary, the value received from accurate well analysis presents a strong return on investment.

Documentation and Quality Control in Production Logging

Effective log management, standardized formats, and forward planning are essential for maintaining quality control and maximizing the long-term utility of production log data. Some key practices to consider include:

Aggregating and centralizing logs into a single management system

Enhancing monitoring and analysis capabilities

Standardizing log formats for consistency

Implementing forward planning strategies

By following these practices, you can ensure that your production log data is well-managed and serves as a cornerstone of quality control.

Protecting sensitive information within logs with measures such as encryption and access control ensures integrity and confidentiality, crucial components of a quality production logging operation within the wellbore. Adopting a consistent, machine-readable log format, such as JSON, facilitates automated analysis and supports quality control through systematic log management.

A defined log retention policy is instrumental in controlling costs by outlining procedures for archival or purging, contributing to efficient production logging operations.

Summary

Production logging is an essential service in the oil and gas industry, providing crucial insights into well performance and condition within the wellbore during production. Through a combination of expert knowledge, advanced tools, and specialized software solutions, production logging offers a comprehensive understanding of well conditions and fluid movements.

The value of production logging extends beyond data acquisition. It offers a means to identify and address production declines, high water production, and efficiency of completion. It also aids in reservoir management, well performance improvement, and problem diagnosis. The advancements in technology and software solutions like PLATO have further enhanced the accuracy and reliability of production logging data. With proper training and application, production logging can significantly enhance well performance and provide a strong return on investment.

Frequently Asked Questions

What is the purpose of the Pre-Job meeting in production logging?

The purpose of the Pre-Job meeting in production logging is to outline and discuss specific objectives for running production logging services, helping to identify areas of production decline, water production, and completion efficiency. This is crucial for the success of the logging operation.

What production logging tools and equipment are used during production logging?

A variety of high-quality tools and equipment, such as wireline, slickline, tractor, and coil, are utilized during production logging to ensure accurate results.

What software is used for interpretation during the post job analysis in production logging?

The software used for interpretation during post job analysis in production logging is PLATO, known for its accurate and reliable results, and widely used by oil & gas operators globally.

What expertise does the staff have in production logging?

The staff has extensive expertise in production logging, with field engineers possessing decades of experience in wireline and petroleum engineering, along with master's and PhD level engineers specializing in multiphase production physics and reservoir engineering.

What can be downloaded from the website related to production logging?

You can download example documents, presentations, and graphics from the website related to production logging.

COMPANY NEWSLETTERS