Blog

Enhanced Efficiency with Array Production Logging Techniques

Key Takeaways

Array Production Logging (APL) provides critical insights into wellbore conditions and fluid dynamics, optimizing reservoir production and management.

Technological advancements in array production logging, including sophisticated sensors and tools, enable precise measurements in various well environments, enhancing production strategies.

Effective pre-job planning and real-time data analysis are essential for maximizing production efficiency, allowing operators to manage resources effectively and address complex production challenges.

Understanding Array Production Logging

Array Production Logging (APL) is a cornerstone technique in the oil and gas industry, offering detailed insights into wellbore conditions and fluid flow properties. These insights are critical for making informed decisions that enhance long-term reservoir production. By facilitating the assessment of fluid movement and reservoir performance, production logging services play a vital role in optimizing the efficiency and accuracy of extraction processes.

When considering production logging services, it is essential to account for factors such as flow regime, well geometry, and completion type. A well’s production flow profile must be understood to develop strategies that maximize efficiency and ensure sustainable reservoir management.

This article explores the evolution of array production logging and the key components and sensors that make it effective.

The Evolution of Array Production Logging

The journey of array production logging began with the pioneering efforts of Eagle Reservoir Services, a key player in the industry. Collaborating with SONDEX, Eagle Reservoir Services developed advanced prototypes that have significantly enhanced the efficiency and accuracy of production logging techniques. This collaboration resulted in innovations that transformed the way fluid dynamics and wellbore conditions are analyzed, providing operators with the tools needed to optimize production strategies.

These technological advancements have had a profound impact on the oil and gas industry, enabling more precise and reliable production logging services. The ability to accurately assess fluid movement and reservoir performance has led to improved resource management and enhanced production outcomes, making array production logging an indispensable tool in the energy sector, particularly in the context of natural gas and fossil fuels.

Key Components and Sensors

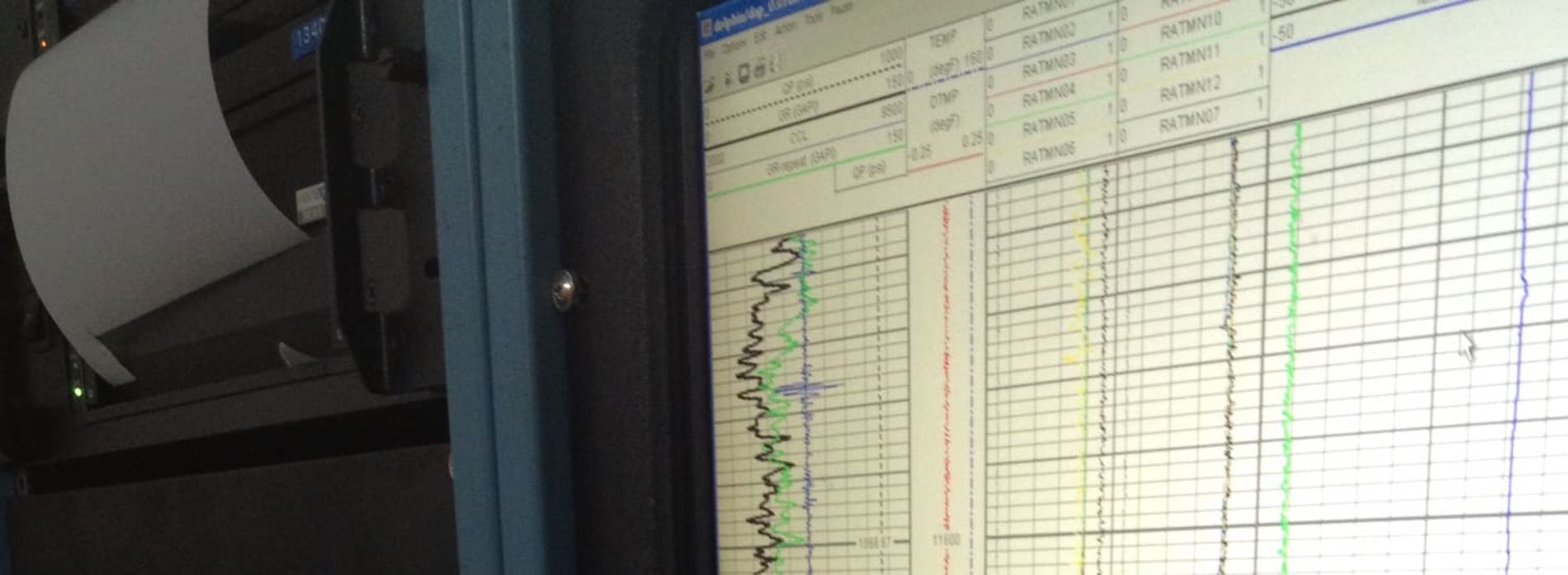

The effectiveness of array production logging is largely attributed to the sophisticated sensors and tools used in the process. The IntelliFlow logging service, for instance, includes a variety of sensors such as resistivity sensors, capacitance sensors, optical fluid ID sensors, and micro-spinners. These sensors are crucial for obtaining accurate and comprehensive measurements of fluid flow dynamics.

In the IntelliFlow array production logging service, sensors are arranged on six arms in a circumferential pattern around the wellbore, providing multiple data points for precise fluid analysis. This configuration allows for cross-sectional measurements of flow properties and characteristics, offering a detailed visualization of fluid dynamics within the wellbore. This setup is particularly effective in various well completion types, including open-hole, cased-hole, gravel-packed, and slotted-liner, as well completions cases can vary significantly, impacting flow rates. The casing collar locator enhances the accuracy of these measurements, with more than half the sensors positioned strategically to optimize data collection and casing measurements in a single run. Baker Hughes.

Furthermore, the array production logging services are suitable for different types of wellbores, such as vertical, highly deviated, and horizontal. This versatility ensures that accurate fluid measurements can be obtained regardless of the well’s geometry, making array production logging an invaluable tool for optimizing production in diverse well environments.

Comprehensive Wellbore Analysis

Comprehensive wellbore analysis is essential for effective reservoir management and production strategies. Array production logging enhances this analysis by utilizing multiple sensors to provide detailed insights into fluid dynamics within the wellbore. This approach allows for a more accurate assessment of production zones, leading to optimized resource management and increased production efficiency.

By leveraging the advanced capabilities of array production logging, operators can gain a deeper understanding of combined fluid flow properties and density dynamics, enabling them to make informed decisions that enhance overall production outcomes.

The following subsections will delve into the specifics of detailed fluid flow imaging and addressing complex production solutions challenges in the world.

Detailed Fluid Flow Imaging

Advanced imaging technologies play a critical role in visualizing fluid dynamics within the wellbore. The IntelliFlow service offers high-definition imaging that provides refined control over production processes by accurately assessing fluid velocity and phase identification in complex well geometries. Utilizing various sensors, array production logging tools can capture fluid velocity and phase identification, even in intricate flow environments.

Fluid Scanning Imaging (FSI) technology is particularly effective in capturing measurements in complex flow regimes, ensuring that operators have a clear and accurate understanding of fluid dynamics. This detailed imaging is crucial for optimizing production processes and enhancing overall efficiency.

Addressing Complex Production Challenges

The ability to identify and address complex production challenges is one of the key advantages of advanced production logging technology. Precise measurements and early detection of flow anomalies through production logging help mitigate costly production interruptions. This approach enables companies to manage complex flow issues more effectively, ensuring smoother and more efficient production processes.

Pressure measurements from strain gauges and manometers offer valuable insights into wellbore conditions, aiding in operational decisions and enhancing the ability to address complex production challenges. This level of precision is crucial for maintaining optimal production efficiency and managing resources effectively.

Maximizing Production Efficiency

Maximizing production efficiency is a top priority in the energy industry, as it directly impacts the global economy and the sustainability of energy resources. Effective planning and production logging are key components in achieving this goal. By systematically addressing all logging objectives, operators can optimize their operations and ensure that specific production goals are met, aligning with energy policy and utilizing an energy source.

Aligning team objectives with production logging goals in the planning process is vital for operational success. This ensures that all aspects of the production logging process are addressed, leading to enhanced efficiency and optimized resource management.

The following subsections will explore how array production logging can optimize horizontal wells and manage water-producing zones.

Optimizing Horizontal Wells

Horizontal wells present unique challenges and opportunities for production optimization. The use of advanced array production logging tools, such as the FAST tool, significantly improves measurement accuracy and data quality in horizontal wellbores environments. These tools provide essential data for accurately analyzing fluid velocities and phase identification, which are crucial for effective reservoir management.

Array production logging technology allows for precise measurement of fluid dynamics in horizontal wells, enabling operators to optimize production by accurately assessing oil and gas production flow. This technology can detect phase holdups and fluid velocities, allowing for targeted strategies to maximize production from different well deviation intervals.

Managing Water-Producing Zones

Managing water-producing zones is a critical aspect of maximizing production efficiency. Ongoing data collection from production logs helps refine operational strategies and improve overall well performance. Continuous monitoring of production data allows operators to formulate targeted strategies to manage produced water and optimize resource allocation.

Fracturing programs are also evaluated during pre-job planning to ensure effective fluid flow and optimize production outcomes. Addressing these factors helps to increase production efficiency and manage water-producing zones more effectively.

Advanced Software for Production Logging Analysis

Advanced software plays a pivotal role in production logging analysis, providing the precision and reliability needed for effective decision-making. PLATO, a software used globally by oil and gas operators, stands out for its ability to interpret production logging data accurately and reliably. Eagle Reservoir Services employs PLATO for post-job analysis, enabling informed decisions in asset management through comprehensive data interpretation.

Running production logging tools alongside reservoir evaluation services enhances measurement accuracy and operational efficiency. The immediate data provided by production logs allows operators to monitor reservoir conditions and trends effectively, leading to more informed storage and timely decision-making.

The following subsections will delve into the specific benefits of using PLATO software and the role of expert analysis in production logging.

Benefits of Using PLATO Software

The IntelliFlow array production logging service provided by PLATO offers unrivaled production monitoring capabilities. This software is crucial for accurate and reliable data analysis in the oil and gas industry, enabling operators to make informed decisions that enhance production efficiency and resource management.

Expert Analysis and Decision Support

Ongoing monitoring through production logs facilitates informed decisions for future improvements, ultimately boosting well productivity. Post-job analysis plays a critical role in evaluating production efficiency and identifying areas for improvement, ensuring that operators can optimize their asset management strategies.

Enhanced productivity is achieved when operators leverage insights gained from thorough post-job analyses. By making informed decisions based on detailed data analysis, operators can implement strategies that optimize production and refining enhance overall efficiency.

Real-Time Insights and Reservoir Management

Real-time insights from production logging data are invaluable for effective reservoir management. Tools like PLATO employ global statistical modeling, utilizing the entire dataset alongside surface information to provide a detailed visual representation of well activity. This probabilistic approach enhances reliability and accuracy in production logging, leading to more informed decision-making for optimization.

Innovative tools streamline the process of analyzing production logging data by managing different file formats and accommodating data from various logging instruments. This capability ensures that operators have access to the most accurate and comprehensive data for making timely and effective decisions.

The following subsections will explore how real-time data aids in diagnosing well issues and enhancing future enhancements.

Diagnosing Well Issues

Real-time data from production logs enables swift identification of well issues, allowing operators to adjust production strategies more effectively. Using live data, operators can pinpoint specific well problems, enhancing their ability to manage production methods and optimize extraction efficiency.

Advanced logging tools are particularly effective in identifying water influx from producing zones, allowing operators to manage water production and improve overall extraction efficiency. By precisely locating water influx, targeted strategies can be implemented to mitigate water production and optimize oil recovery.

Enhancing Future Enhancements

Continuous monitoring of production logging provides critical data that guides future enhancements and improves overall well performance. Real-time insights from production logs are essential for effective reservoir surveillance and management, aiding in diagnosing well issues and optimizing production.

Expert analysis and decision support from analysts based on production logging data are crucial for optimizing asset management and guiding future enhancements. By leveraging detailed data analysis, operators can implement strategies that enhance production efficiency and ensure sustainable resource management.

Pre-Job Planning and Execution

Thorough pre-job planning is essential for aligning service objectives with performance enhancement goals in production logging operations. Effective pre-job discussions help clarify objectives and align expectations, ensuring that all operational parameters are fully understood in advance.

By identifying potential challenges and aligning team objectives, thorough preparation before production logging can significantly enhance the success rate of operations. The following subsections will discuss the importance of addressing drilling trajectory and frac programs, as well as meeting defined objectives during pre-job planning.

Drilling Trajectory and Frac Programs

Pre-job discussions are critical to ensuring the success of production logging operations. During these discussions, topics such as drilling trajectory and frac programs are comprehensively addressed to identify potential challenges that may impact logging efficiency.

Effective frac programs are essential for optimizing well performance and enhancing production outcomes. Addressing these factors during pre-job planning ensures all aspects of the formation evaluation and production logging process are optimized for success.

Meeting Objectives

Thorough planning is crucial to align the production logging process with defined objectives, ensuring that all data requirements are adequately met. By focusing on the importance of efficiency and quality, operators can create value for their customers while meeting business goals.

Organizations must work in conjunction with their teams to ensure that all performance targets are achieved. Maintaining a clear focus on objectives and detailed planning contribute to overall operational success and enhances the effectiveness of production logging within the organization, particularly in the realm of marketing.

Summary

In conclusion, array production logging techniques offer unparalleled insights into wellbore conditions and fluid flow properties, significantly enhancing production efficiency in the oil and gas industry. By leveraging advanced sensors, detailed fluid flow imaging, and comprehensive wellbore analysis, operators can optimize their production processes and manage complex challenges effectively.

The integration of advanced software like PLATO and thorough pre-job planning further enhances the success of production logging operations. Continuous monitoring and expert analysis provide real-time insights that guide future enhancements, ensuring sustainable resource management and optimized production outcomes. As the energy industry continues to evolve, the adoption of array production logging techniques will play a critical role in meeting global energy demands and driving economic growth.

Frequently Asked Questions

What company began Array Production Logging?

Array Production Logging was initiated by Eagle Reservoir Services.

With which company did Eagle Reservoir Services work to run prototypes for production logging?

Eagle Reservoir Services collaborated with SONDEX to run prototypes for production logging.

What software is used for production logging analysis by Eagle Reservoir Services?

Eagle Reservoir Services utilizes PLATO for production logging analysis.

What is the purpose of the pre-job discussion in production logging?

The purpose of the pre-job discussion in production logging is to ensure all operational parameters are clearly understood by covering the drilling trajectory, frac programs, and objectives to be met. This step is crucial for the success of the operation.

What is the role of Eagle Reservoir Services after the production logging job?

Eagle Reservoir Services plays a critical role in analyzing production logging data and assisting in decision-making regarding asset management. Their expertise ensures that informed choices are made to enhance operational efficiency.

COMPANY NEWSLETTERS