Blog

Mastering Reservoir Engineering: Essentials for Optimizing Oil and Gas Recovery

Mastering Reservoir Engineering: Essentials for Optimizing Oil and Gas Recovery

What is reservoir engineering, and how does it drive oil and gas production efficiency? This discipline is pivotal in extracting maximum value from energy resources. This article explores the critical role that reservoir engineers play in fostering the most productive means to manage and enhance hydrocarbon recovery.

Key Takeaways

Reservoir engineers play a pivotal role in optimizing hydrocarbon recovery by merging geology, engineering, and applied mathematics for accurate reservoir characterization, performance prediction, and management of operations.

Advanced technological tools such as integrated production data analysis, innovative enhanced oil recovery (EOR) methods, and AI-driven decision support systems are instrumental in improving oil and gas extraction and tailoring recovery to specific reservoir conditions.

Innovations in reservoir surveillance and economic strategies are crucial, with engineers applying dynamic modeling, real-time monitoring, and cost-effective depletion tactics to ensure maximum value from oil and gas fields while accommodating financial and environmental considerations.

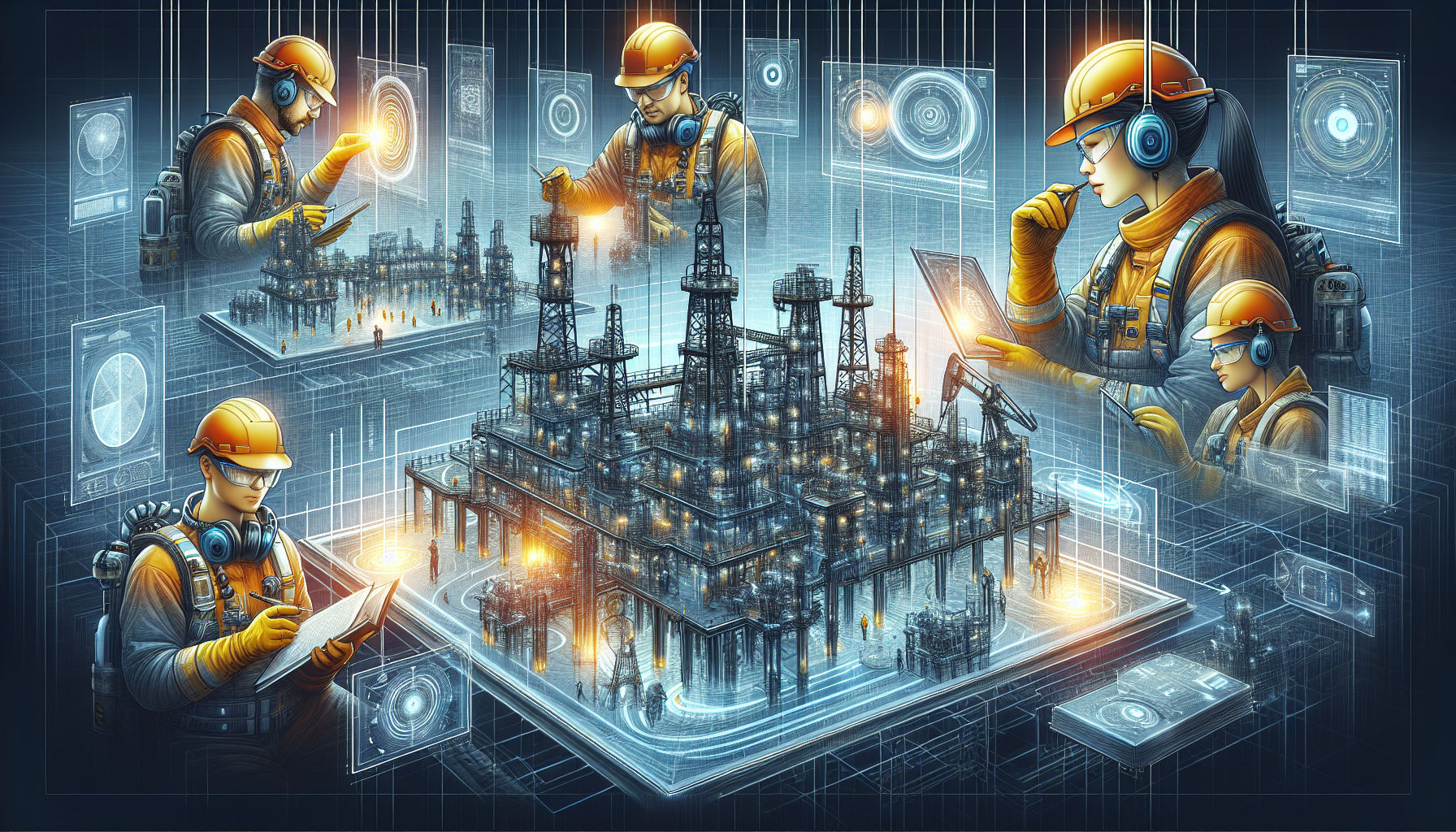

The Role of Reservoir Engineers in Oil and Gas Exploration

Reservoir engineers are the masterminds behind the scenes in oil and gas exploration, orchestrating the entire process from start to finish. These professionals strive to extract the most value from oil and gas fields by accurately identifying and characterizing reservoirs, predicting their performance, and managing both costs and operations effectively. This is a meticulously calculated, high-stakes task, requiring a deep understanding of the reservoir, achieved through the synthesis of geologic and engineering data.

This interdisciplinary approach brings together subsurface geology applied mathematics, geology, and physics, utilizing a rigorous analytical framework to inform decision-making processes. The role of reservoir engineers often involves specializing in reservoir conditions and optimizing operations to maximize hydrocarbon recovery.

Such knowledge aids in pinpointing the most economically viable reservoir depletion schemes and well locations, as well as development strategies for oil and gas reservoirs.

The Intersection of Geology and Engineering

Reservoir engineers don’t just dabble in geology—they fully immerse themselves in it. Their work entails employing geological techniques alongside reservoir mechanics to achieve a comprehensive understanding of how the reservoir behaves as a system. This approach goes beyond the surface, diving deep into subsurface geology to:

Generate accurate models of the earth’s crust

Identify potential reservoirs

Determine the properties of the rock formations

Analyze the fluid flow within the reservoir

By combining their knowledge of geology and reservoir mechanics, reservoir engineers are able to make informed decisions about the extraction and production of oil and gas.

The complexity of the task demands a holistic approach, harmonizing information from:

geological

petrophysical

geophysical

engineering fields

By capturing the complex nature of subsurface environments, reservoir engineers can accurately predict how the reservoir will behave under different conditions. This intricate interplay between geology and engineering is a testament to the dynamic nature of the field and the vital role that reservoir engineers play in oil and gas extraction.

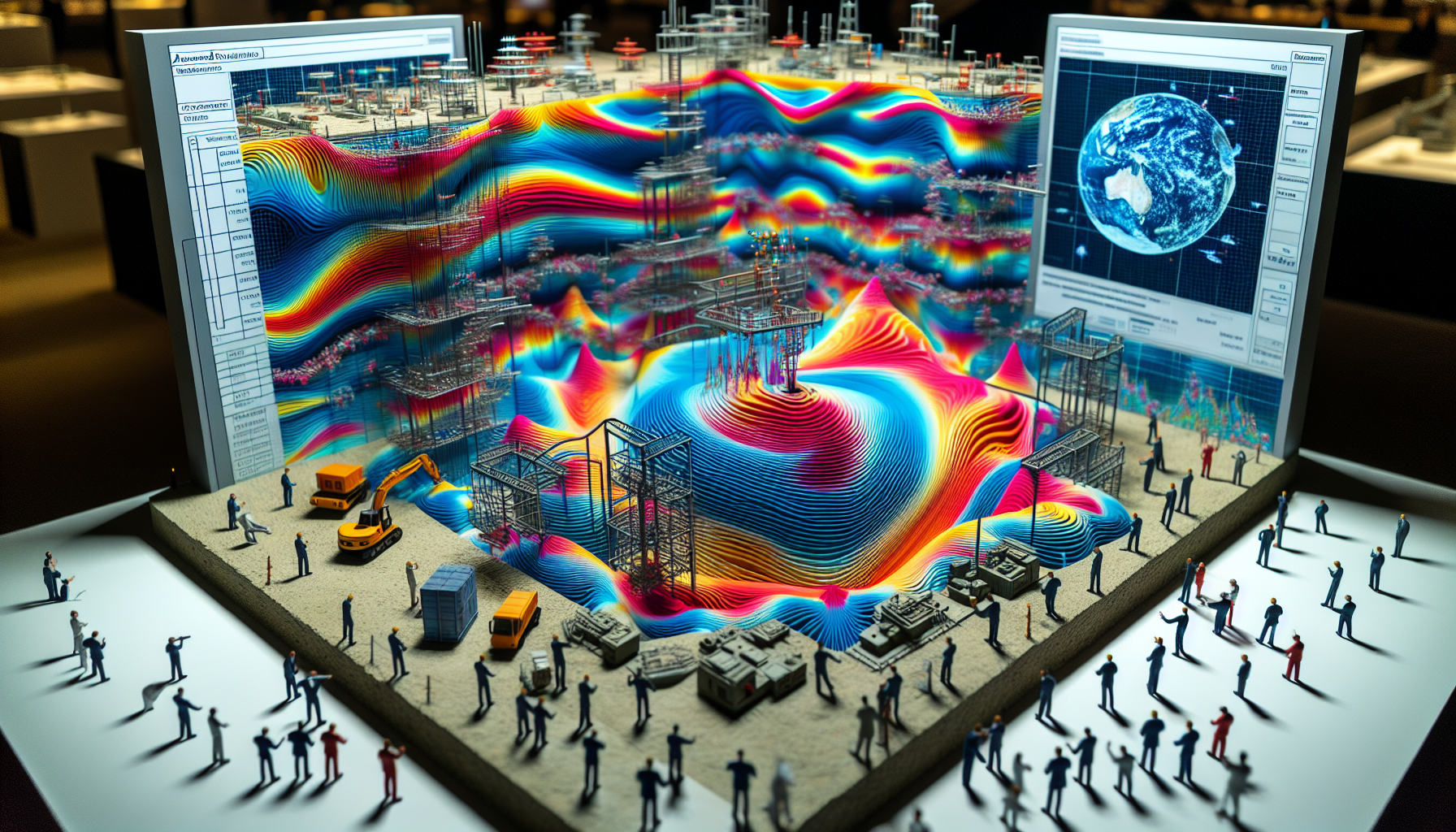

Applied Mathematics in Reservoir Simulations

The world of reservoir engineering is steeped in numbers. Reservoir engineers use applied mathematics to create numerical reservoir modeling production, simulating physical and chemical processes in reservoirs. These models are instrumental in evaluating different production scenarios and assessing reservoir performance.

Primarily, reservoir simulators serve to anticipate production performance, calculate ultimate gas recovery, and plan efficient well completions. They allow reservoir engineers to play out different scenarios in a controlled environment before taking action in the real world. This predictive capability is central to decision-making, securing the most efficient resource utilization and maximum yield from oil and gas reservoirs.

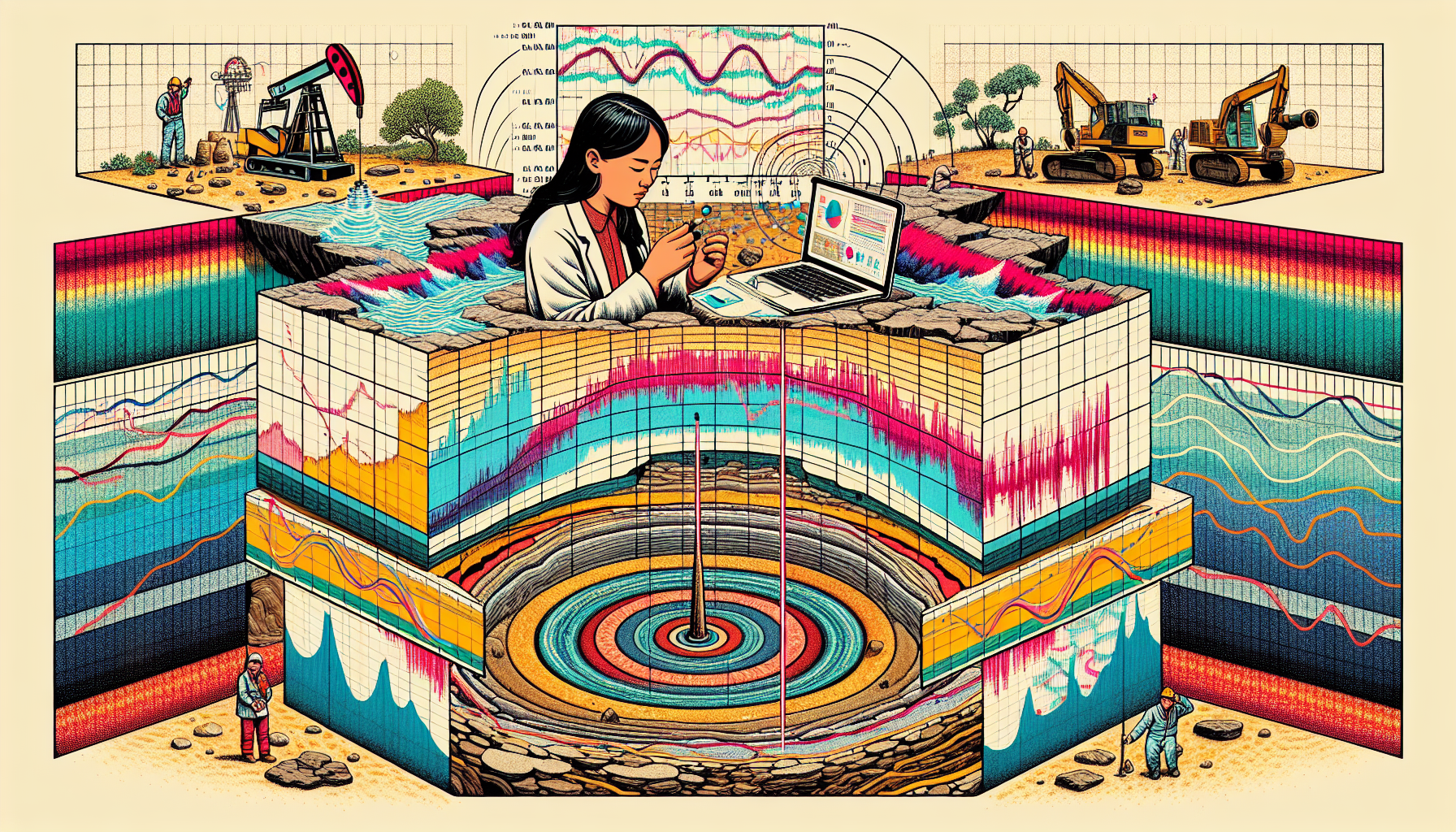

Advanced Techniques in Reservoir Characterization

Beyond the basic principles of geology, engineering, and mathematics, reservoir engineers employ advanced techniques in reservoir characterization. The complex method takes advantage of seismic imaging, well logs, and geological studies to visualize the geology and ascertain the production potential of reservoirs, a key aspect for precise development planning.

These techniques pave the way for a deeper understanding of reservoir behavior and production strategies.

Integrating Production Data for Enhanced Recovery

In reservoir engineering, insights from the past are invaluable for future planning. Historical production data from existing wells can be analyzed using techniques like rate-transient analysis and flow simulation to discern trends in reservoir performance and guide future production strategies. This rich source of information serves as a roadmap, helping engineers navigate the complexities of reservoir management.

Moreover, AI-driven decision support systems have come to the fore, analyzing real-time production data and enabling autonomous operations. These systems offer recommendations for action to improve reservoir performance, providing reservoir engineers with a cutting-edge tool to enhance recovery and optimize production.

Tailoring Recovery Methods

Enhancing oil recovery is not a one-size-fits-all operation. Each reservoir has unique characteristics that demand a tailored approach. Reservoir engineers implement enhanced oil recovery (EOR) techniques to maximize the volume of oil extracted from reservoirs beyond what is possible with primary and secondary recovery methods.

Chemical EOR techniques such as polymer flooding, surfactant flooding, and alkali-surfactant-polymer (ASP) flooding are used to change fluid dynamics, enhancing oil displacement and improving sweep efficiency in the reservoir. These techniques, enhanced by machine learning applications, refine production strategy optimization, incorporating dynamic reservoir conditions and improving the accuracy of prediction models for EOR.

Fluid Dynamics in Reservoir Management

Fluid dynamics play a critical role in reservoir management. The movement and interaction of fluids within reservoirs can significantly impact production strategies. Advanced modeling and simulation software allow reservoir engineers to more accurately predict fluid behavior, estimate reserves, and plan optimal production strategies.

The integration of artificial intelligence and machine learning into reservoir surveillance has revolutionized the field, contributing to:

Predicting future reservoir behaviors

Enhancing proactive management

Providing reservoir engineers with powerful tools to manage the complex dynamics of fluid flow within reservoirs

Maximizing hydrocarbon recovery

Ensuring efficient reservoir management.

Maximizing Hydrocarbon Recovery

One of the keys to maximizing hydrocarbon recovery lies in tailoring extraction techniques to specific reservoir types. From steam injection for heavy oil to polymer flooding for conventional fields, these tailored approaches optimize hydrocarbon recovery.

Innovative recovery methods, such as CO2 and nitrogen injection, have led to substantial increases in oil and gas production in fields like the Permian Basin and Weyburn-Midale in Canada. These success stories underscore the significant potential of enhanced oil recovery (EOR) techniques in maximizing hydrocarbon recovery, including natural gas and crude oil natural gas.

Curve Analysis Material Balance in Forecasting

Forecasting future production performance is a critical aspect of reservoir management. Reservoir engineers use production forecasting techniques such as decline curve analysis, material balance methods, and analysis material balance modeling to predict a well’s production over time. By utilizing reservoir modeling production forecasting, they can make more informed decisions about reservoir development and management.

Identifying the type of decline—be it hyperbolic or exponential—is a critical first step. By constructing specific plots such as rate-time and rate-cumulative plots, engineers can identify the decline type and forecast future production performance of the well.

These predictive tools play a vital role in making informed decisions about well operations, helping to ensure the sustainability and profitability of the reservoir.

Innovations in Reservoir Surveillance and Monitoring

In the rapidly evolving field of reservoir engineering, innovation is key. The advent of digital twin technology allows engineers to create virtual models of reservoirs, simulating various scenarios and predicting outcomes in real-time for better decision-making.

Advanced analytics tools have also become invaluable, aiding in the handling and interpretation of large datasets from reservoir operations. These innovations, combined with smart reservoir surveillance engineering i.e monitoring systems that autonomously gather and evaluate sufficient data from different sources, enhance the precision and efficiency of reservoir monitoring.

This proactive approach to reservoir management ensures that operations remain at the cutting edge of industry advancements.

Dynamic Reservoir Conditions Tracking

One of the significant advancements in reservoir surveillance and monitoring is the ability to track dynamic reservoir conditions. AI-powered systems in reservoir management enable real-time decision-making by continuously assessing dynamic conditions and supporting timely interventions.

The integration of tracer data into reservoir simulation models improves the prediction of fluid behavior for better management decisions. Additionally, the application of nanoparticles enhances surfactant or polymer flooding, reducing chemical adsorption on rock surfaces and improving displacement efficiency. This technological revolution in reservoir engineering has resulted in significant operational efficiencies and cost savings.

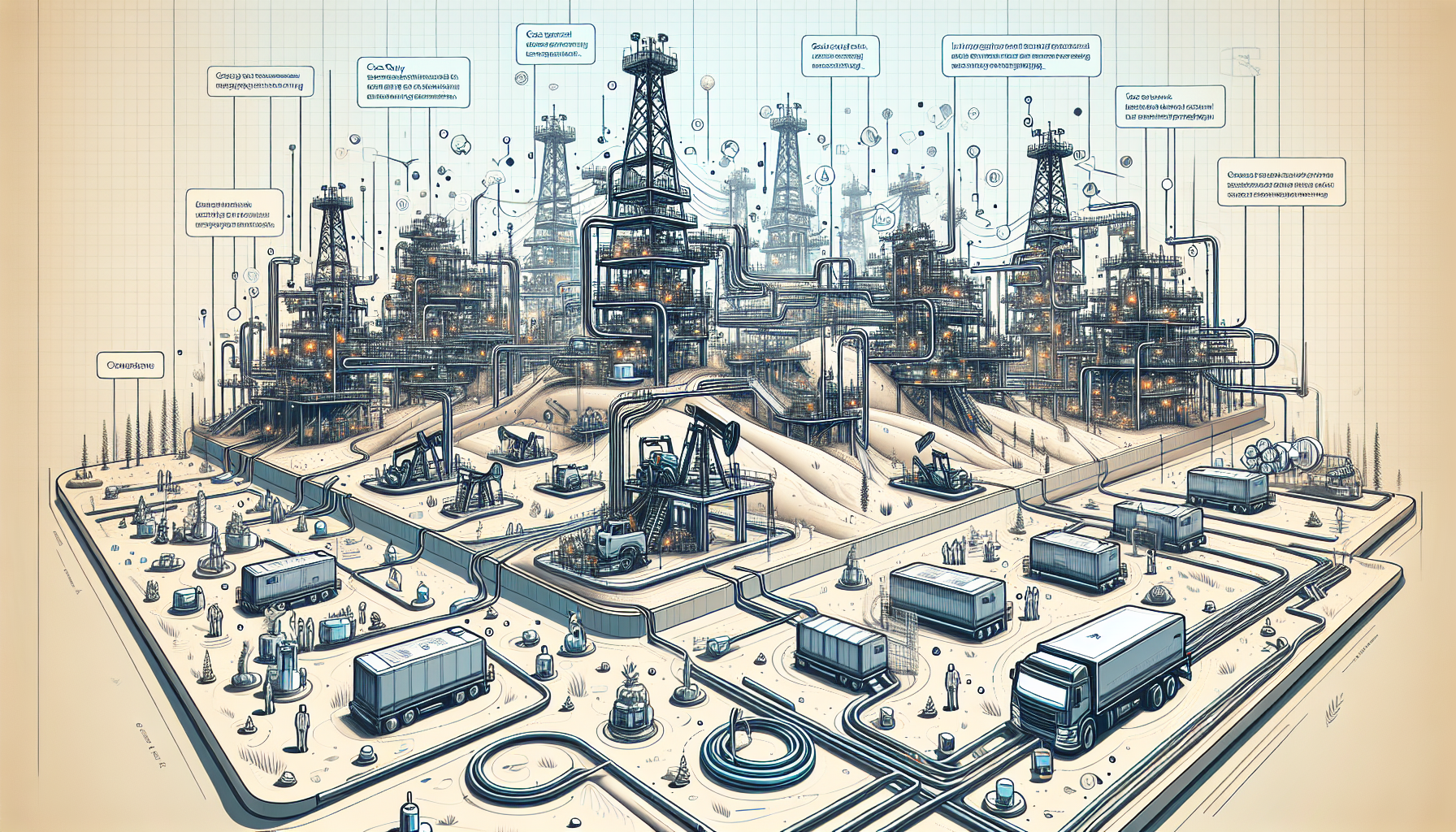

Economic Aspects of Reservoir Engineering

Economics underpins every facet of reservoir engineering. From well drilling to workover planning economic modeling and numerical reservoir modeling, every decision made by a reservoir engineer has financial implications.

Regular review and updates to reservoir development plans are essential to determine optimal development plans, with adjustments to well and operations aimed at:

optimizing resource recovery

maximizing economic value

aligning with stakeholder expectations

navigating project limitations and uncertainties

keeping costs low

Such strategies must aim to maximize hydrocarbon recovery while keeping costs low.

Cost-Effective Strategies for Reservoir Depletion

Within the economic aspects of reservoir engineering, one area stands out: cost effective reservoir depletion. Effective reservoir depletion schemes involve evaluating reservoir features, such as pressure support and the necessity for infill drilling, to inform drilling and workover operations that maintain cost-effective, steady production rates.

Enhanced oil recovery methods guided by accurate reservoir characterization are employed in over 60% of oil fields globally to ensure economically viable extraction throughout a field’s productive life. These strategies highlight the financial acumen of reservoir engineers, who often need to determine how much oil can be extracted while aiming for profit maximization and keeping costs low.

Case Studies: Success Stories in Reservoir Engineering

Just as the proof of the pudding lies in the eating, in reservoir engineering, the evidence is in the outcomes. Case studies such as the Goldsmith Andector Unit in West Texas bear testament to the success of integrated reservoir engineering methods, where the application of a waterflood expansion alongside reservoir engineering significantly optimized production performance.

Enhancing Production in Mature Fields

Enhancing production in mature fields is a significant challenge that reservoir engineers face. Here, a multidisciplinary approach and innovative recovery techniques come into play. In the Gandu field, the focus on reservoir characterization and well performance monitoring led to an improvement in its production, including workovers and recompletions.

In the Mangala Field in India, the introduction of microbial enhanced oil recovery techniques led to an increase in oil recovery rates by up to 15%. Similarly, optimization of waterflooding in a mature oil field resulted in a 20% increase in production. These success narratives illustrate how pioneering techniques and strategies can revitalize mature fields, boost production, and guarantee their economic sustainability.

Navigating Challenges in Unconventional Reservoirs

Unconventional reservoirs present their own unique set of challenges. These reservoirs, characterized by complex rock-fluid interactions, contribute to significant heterogeneity and a shorter production span, making estimating hydrocarbon production more uncertain.

To manage the low permeability of unconventional gas reservoirs, like shale and tight gas plays, advanced techniques like hydraulic fracturing are employed to enhance hydrocarbon flow. These dedicated recovery methods highlight the resilience and creativity of reservoir engineers in surmounting the difficulties presented by unconventional reservoirs.

Addressing Complexities in Shale and Tight Gas Plays

Addressing complexities in shale and tight gas plays is a significant aspect of managing unconventional reservoirs. These reservoirs, characterized by extremely low permeability, require specialized recovery techniques unlike those used in conventional reservoirs.

Hydraulic fracturing enhances permeability by creating fissures in the rock formation, allowing hydrocarbons to flow. Acidizing used in conjunction with hydraulic fracturing can further improve recovery from tight formations. The implementation of multistage fracturing increases contact with the reservoir and improves extraction rates.

Thanks to advancements in 3D seismic imaging technology and the application of microseismic monitoring during hydraulic fracturing, reservoir engineers can hone the fracture design and enhance the operation’s efficiency.

Summary

Reservoir engineering is a dynamic and complex field, integrating geology, physics, and mathematics to optimize hydrocarbon recovery. From the role of reservoir engineers in oil and gas exploration to the challenges in unconventional reservoirs, this field is constantly evolving, with new techniques and technologies being adopted to meet the demands of the industry. With advancements in simulation software, surveillance systems, and recovery methods, reservoir engineers continue to push the boundaries, ensuring the sustainable and profitable extraction of oil and gas.

Frequently Asked Questions

What is the role of a reservoir engineer?

Reservoir engineers play a crucial role in maximizing profit and managing operations effectively in oil and gas exploration by utilizing geology, mathematics, and physics to accurately identify and characterize reservoirs, predict their performance, and make informed decisions about well operations.

What is reservoir characterization?

Reservoir characterization involves using seismic imaging, well logs, and geological studies to map out the geology and determine the production potential of reservoirs. It is crucial for accurate development planning and production strategy.

How are fluid dynamics important in reservoir management?

Fluid dynamics are crucial in reservoir management, as they help in predicting behavior and optimizing production strategies through advanced modeling and simulations. Understanding fluid movement within reservoirs has a significant impact on production strategies.

What are some of the challenges in unconventional reservoirs?

Estimating hydrocarbon production in unconventional reservoirs is challenging due to significant heterogeneity and a shorter production span, resulting from complex rock-fluid interactions. Advanced techniques like hydraulic fracturing are used to manage the low permeability and enhance hydrocarbon flow.

What are some of the economic aspects of reservoir engineering?

Reservoir engineering encompasses economic modeling, well planning, and development strategies to optimize resource recovery and maximize economic value through efficient operations and cost minimization. This involves making decisions that balance hydrocarbon recovery with cost-effectiveness.

COMPANY NEWSLETTERS